Published in Nacional number 644, 2008-03-17

INGRA IN THE ECO-INDUSTRY

'We will make diesel fuel out of algae'

Václav Hlavatý and Rajko Vuckovic, Ingra directors responsible for setting up a biodiesel production facility, reveal why Croatia's leading construction engineering company is turning to industry

Václav Hlavatý i Rajko VučkovićIngra, a Croatian company, has launched the most ambitious Croatian biodiesel production project ever. Ingra intends to build a large biodiesel production facility in the port area near Slavonski Brod, and Rajko Vuckovic, the director of Ingra daughter company Bioadria, and Marijan Juric, the head of the Slavonski Brod port authority, were there on 21 February to sign a contract on the lease of land in the Port of Slavonski Brod on which the biodiesel production facility is to be built.

Václav Hlavatý i Rajko VučkovićIngra, a Croatian company, has launched the most ambitious Croatian biodiesel production project ever. Ingra intends to build a large biodiesel production facility in the port area near Slavonski Brod, and Rajko Vuckovic, the director of Ingra daughter company Bioadria, and Marijan Juric, the head of the Slavonski Brod port authority, were there on 21 February to sign a contract on the lease of land in the Port of Slavonski Brod on which the biodiesel production facility is to be built.

In Slavonski Brod Ingra intends to produce 150 thousand tonnes of biodiesel a year. They have launched the project with the intention of turning a profit, but also to contribute to the preservation of the environment. Biodiesel is a fuel that is used as an alternative to classic crude oil derivates, and is mixed into crude oil derivates, which reduces the effect of harmful emissions on the environment. Any diesel vehicle manufactured after 1995 can use Biodiesel, and its energy value is equal to that of mineral fuels. It is a motor fuel that is obtained through esterification with methanol from rapeseed oil or other grains and has the same energy value as mineral fuels, and can entirely replace crude oil-derived diesel in diesel engines. It is used in various forms and technological procedures and is entirely harmless for the environment. It decomposes completely in water in only 28 days, while crude oil needs 40 years to do so. Biodiesel's many positive characteristics make it the only fuel permitted in organic agriculture, and it is nowadays impossible to get an EU certification of the purity of organically produced agricultural products without using it.

Igor Oppenheim i Tomislav DragičevićThe European Union has given its member states strict conditions to replace as much as 20 percent of traditional fuels with biodiesel by 2020. The share is currently 4.5 percent. There is still not enough biodiesel being produced in Europe, making the market to place these products very large. The Ingra facility is to be one of the largest in Europe. One like it, with a capacity of 150 tonnes a year, was recently opened in Hungary, and there is a 250 thousand tonnes a year facility under construction in Spain. Embarking into the production of biodiesel is only one of the ecologically aware projects that Ingra plans to get involved in the future.

Igor Oppenheim i Tomislav DragičevićThe European Union has given its member states strict conditions to replace as much as 20 percent of traditional fuels with biodiesel by 2020. The share is currently 4.5 percent. There is still not enough biodiesel being produced in Europe, making the market to place these products very large. The Ingra facility is to be one of the largest in Europe. One like it, with a capacity of 150 tonnes a year, was recently opened in Hungary, and there is a 250 thousand tonnes a year facility under construction in Spain. Embarking into the production of biodiesel is only one of the ecologically aware projects that Ingra plans to get involved in the future.

Václav Hlavatý, the executive director of Ingra, responsible for leading the biodiesel project has this to say to Nacional on this and similar projects: "In the future, Ingra does not intend to participate in only one ecological project. Besides the production of biodiesel, Ingra is simultaneously involved in a development project for the production of bio-fertilizers, wooden palettes and biomass-based fuels. These projects are in various phases, and for some we are already drafting preliminary designs for location permits. Biodiesel is only one of the Ingra projects in the area. Biodiesel has a future, especially as a result of the instability of the crude oil market, and its favourable effect on the environment. There are other replacements for crude oil derivates such as ethanol, which is produced in growing quantities. We are also considering these kinds of projects."

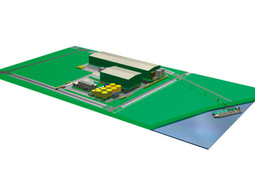

Ingra has picked the river port near Slavonski Brod as the site to build a biodiesel production facility. They made the decision because of its flexibility and the many possibilities for the delivery of raw production materials and shipping of finished products.

"With Slavonski Brod we got the option of transport by river, rail and road. Most of the time spent on preparation was lost, so to say, on the zoning plan that was being drafted in Slavonski Brod, and which is to provide us with everything that was needed. A project to construct a beltway is in the works that would allow us to have a direct connection with the highway. We did not, actually, lose this time, but rather spent it on quality preparations ahead of making numerous key decisions related to production technology. The facility we will build will be worth 58 million euro. The project includes a river barge, elevators that transport raw materials and finished products, and silos", says Rajko Vuckovic, the director of the Bioadria Company, which is leading the biodiesel production project.

Several factors are key to the success of the project, but the most important one appears to be the production technology. At Ingra, they have yet to adopt a final decision on which technology to use, because there are several, they are constantly being improved and they provide for greater profitability. Rajko Vuckovic outlined for Nacional why the choice of production technology was important for Ingra: "The technology we will be using has to be flexible so that we can process not just rapeseed but also all other kinds of oil crops, refuse fats, pork fats from slaughterhouses and the like. There is research going on today on the possibility of using sea algae in the biodiesel production process, so that the technology needs to support as many methods of production as possible. We are paying particular attention to the degree of the utilisation of capacities. At a facility that processes 150 thousand tonnes, even a single percentage in the degree of utilisation can have a profound effect on the company's bottom line profitability. That is why we are being very careful in our selection of production technology that will guarantee long-term profitability. There are companies producing biodiesel today that are not earning a profit only because of a few percentage points of unutilised production capacities. We are trying to make sure that this does not happen to us in the future."

On the long term Ingra feels that the biodiesel production project will be very profitable, otherwise they would not have embarked on the 58 million euro investmentIngra plans to sell the biodiesel it produces in the future to the INA oil company first of all. The European Commission's directives, based on which each member country must make biodiesel account for at least 4.5 percent of total fuel sales on its markets, has opened the way for Ingra to place its entire production of biodiesel to that company. 20 thousand tonnes of biodiesel are currently produced in Croatia at the Ozalj site, the Europamill Company is building a 60 thousand tonnes annual capacity facility in Brsadin, while the remaining production is of significantly lesser capacity.

On the long term Ingra feels that the biodiesel production project will be very profitable, otherwise they would not have embarked on the 58 million euro investmentIngra plans to sell the biodiesel it produces in the future to the INA oil company first of all. The European Commission's directives, based on which each member country must make biodiesel account for at least 4.5 percent of total fuel sales on its markets, has opened the way for Ingra to place its entire production of biodiesel to that company. 20 thousand tonnes of biodiesel are currently produced in Croatia at the Ozalj site, the Europamill Company is building a 60 thousand tonnes annual capacity facility in Brsadin, while the remaining production is of significantly lesser capacity.

"There is a demand for biodiesel and it is at the moment the least of problems. We are not counting only on INA as our potential buyer, but are thinking, rather, much wider. As the market in Croatia currently stands, however, almost the entire production could be placed with INA and there would still not be enough to fulfil the existing obligation arising from the European Commission's directive.

“It is not easy to talk today of the balance of demand and supply on the biodiesel market, because there is a shortage of production capacity in Europe. The European market still produces much less biodiesel than the quantity required by the European Commission directive. It can be assumed that the trend to biodiesel production will continue to grow in the future in order to bolster the economic independence of countries from traditional fuels. The wars that have broken out recently were always close to fuel-rich zones and resulted in a high level of volatility in the prices of crude oil derivates. The negative effects of this price volatility can be significantly reduced by the development of alternative fuel production, above all of biodiesel", says Rajko Vuckovic.

One of the challenges for future biodiesel producers is the land area on which the rapeseed the fuel is to be derived from will be grown. In Croatia, the current yield per hectare of land is 3 to 3.5 tonnes of rapeseed on the average. That is under the European standard, which amounts to 4 to 4.5 tonnes per hectare, and which would also bring a profit to domestic producers. Ingra has engaged the services of two consultancy companies that will contract for and develop the production of rapeseed on its behalf. The goal is to bring the domestic producers up to the European level of yields of rapeseed per hectare, which will earn them a tidy profit.

"During the first years of production we will also have to depend on imports, until domestic producers in Croatia gain confidence. Besides, we can buy raw materials in all phases of processing on the global market. We can buy the seed and press it, or buy already processed oil, depending on what will be more favourable on the market. Croatian agronomists claim that our producers like to grow rapeseed as they have experience in its cultivation. They have, however, up to now had a hard time in placing it on the market. They sold it for the most part as edible oil, and buyers did their best to push down prices as much as they could. Ingra is of a different school of thought. For example, if we are forced to pay 1.7 kuna per kilogram on the global market, then we will also pay this price to domestic producers. We will certainly not blackmail domestic producers with inappropriate price reductions", said Rajko Vuckovic. On the long term Ingra feels that the biodiesel production project will be very profitable, otherwise they would not have embarked on the 58 million euro investment. They do not yet, however, wish to forecast how soon the investment will pay off.

At Ingra they feel that it is a project that will have a positive influence on the overall Croatian economy. They expect the issue of a location permit sometime this spring, to start construction of the facility this year, to complete it within a year's time and to be ready for production in the summer of 2009.

Latest news

-

28.10.2010. / 14:15

'A profitable INA is in everyone's interest'

-

28.10.2010. / 09:38

Sanader’s eight fear SDP — Won’t bring down Government

-

21.10.2010. / 15:02

Interior Ministry turned a blind eye on Pukanic assassination

-

20.10.2010. / 09:34

Barisic could bankrupt HDZ